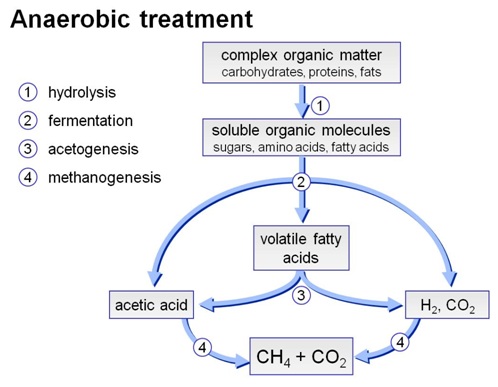

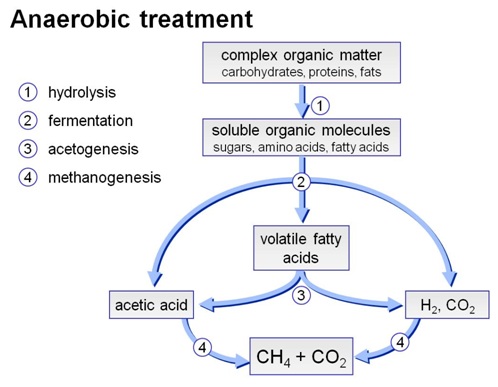

Anaerobic treatment

Anaerobic principle

Anaerobic digestion is a complex process whereby organic pollutants trapped in the liquid effluent are broken down into methane, carbon dioxide and water.

The entire anaerobic degradation reaction is carried out by the consecutives processes sequences of acidogenesis (hydrolysis and acidification) and methanogenesis (transformation into biogas), which can be described as follows:

- In the first step the organic complex (polysaccharides, proteins) is hydrolysed into simple soluble monomers (sugars, amino acids). This part of the reaction is carried out by an exo-enzyme produced by the fermentation bacteria.

- In the following step, the hydrolysates are fermented and converted into volatile fatty acids, hydrogen, carbon dioxide, ethanol and other alcohols as well as lactate. This part of the reaction is called acidogenesis.

- The product of fermentation is converted into acetate, hydrogen and carbon dioxide (acetogenesis) by so-called acetogenic bacteria. Acetogenic bacteria grow in close (almost symbiotic) association with methanogenic bacteria. The reason for such association is that the conversion of fermentation products is thermodynamically possible only if the hydrogen concentration is kept low. This is achieved by the action of the methanogenic bacteria in the final reaction phase.

- The production of methane from hydrogen acetate and carbon dioxide by methanogenic bacteria is the ultimate phase of anaerobic digestion.

- The COD present in the wastewater is then transformed into methane and a small amount of biomass. As the solubility of methane in water is particularly low, this compound escapes as a gas and removes the COD from the effluent.

This process of degradation can bu summarized as follows:

|

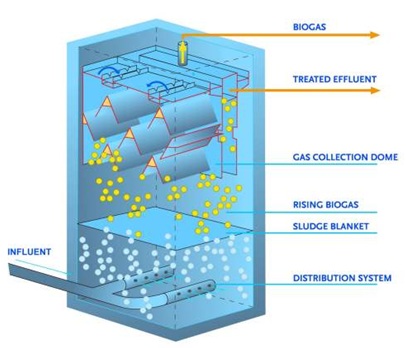

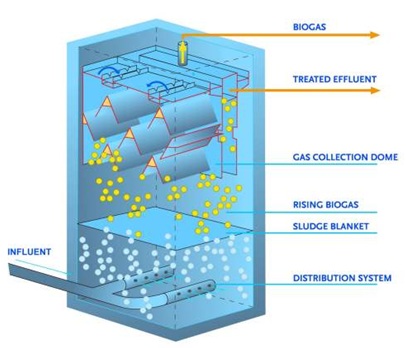

Both processes occur within the same UASB reactor (for Upflow Anaerobic Sludge Blanket)

> Due to its design (specificity of the ENPROTECH process), the UASB reactor generates a set of convection cells and an upflow which, associated with the biogas, causes the flotation of the granular sludge blanket.

> In the lower part, the UASB reactor has a raw water distribution system.

> A 3-phase separator (water-sludge-biogas) caps the top of the reactor, that allows the recovery of biogas in inverted chutes and of the treated effluent by overflow, but above all prevents any discharge of granular sludge thanks to the deflector system in place.

|

Internal schematic view of an UASB reactor

|

In order to ensure and control the upward velocity of the raw water within the reactor, but also to recover the alkalinity and the bicarbonate / carbonate buffer capacity, the effluent is recirculated into a mixing/buffer tank installed upstream of the anaerobic reactor.

This tank allows the pH correction and possible heating of the eflluent.

THE ADVANTAGES OF THE UASB MEDIUM LOAD ANAEROBIC REACTOR:

- Very limited sludge production

- Low energy consumption

- Biogas production as a source of energy

- High volumetric loading, resulting in small reactor volumes

- Can give right to green certificates (management of carbon credits)

Furthermore, the reactor proposed in this offer is :

- of simple and robust design

- proven, reliable and particularly stable

- flexible in its operation

- supervision and reduced maintenance

|

|